Telephone: (+44) (0)843 289 9728

Email: kas at kaspencer dot com

choose one

for sale 2 - (scroll & read me)

AUTOMATIC LABELLING OF STOPS FOR

HAUPTWERK ORGANS - ITEMS FOR SALE

KASpencer offers

components for sale to those who wish to equip their

Hauptwerk organs with Automatic Electronic Stop Labelling.

The components which are not availablke anywhere elase are

offered as a Core Components Kit. With other, readily

available

components, and the accompanying Core Kit

Construction Manual, a cost-effective solution to the

labelling of stops with multiple Hautpwerk sample

sets is

overcome!

1.

THE CORE COMPONENT KIT

A Core Components Kit can be purchased from KASpencer, and

you source the rest of the items yourself. You would then assemble

the stop plate according

to the instructions in the

Electronic Labelling for Hauptwerk Organs Construction Manual.

The manual costs £17 + P&P and is available frome the link immediately

above.

When you have read the manual and are sure that

you can build the project, you may orderthe core kit of

components which are

described below.

Prices were correct

at the time of writing, but you are advised to check prices

before confirming your order.

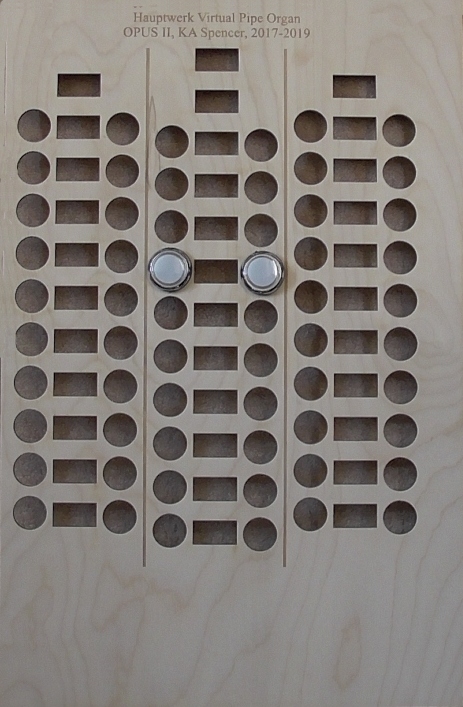

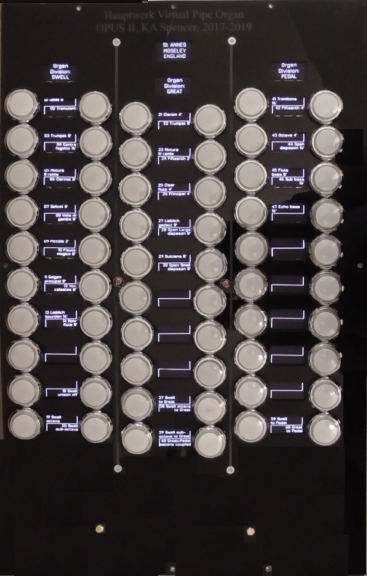

1.1 Stop Plates

These are available

in quality beech ply, and black acrylic, which is a little more expensive.

One plate is required per stop jamb. They are of high quality, and professionally

cut by laser, and supports up to 70 stops per jamb.

Prices are:

Acrylic: £85 each; Beech Ply: £75 each, + P&P.

The plates have circular apertures for fitting the illuminated stop switches

(or solenoid drawstops), and rectangular for the display

of the OLED labels,

Scroll down to see the images of he two plates: on the left is shown the acrylic plate,

fitted with the OLED displays and illuminated stop switches.

On the right is shown the beech ply version, with just two illuminated stop switches in place.

(Scroll down for details of the printed circuit boards).

1.2

Printed Circuit Boards

Three PCBs are required per stop jamb.

The Central PCB holds

12 displays, the lower 10 of which label 20 of the stops.

The top display can provide information about the organ currently loaded.

The second display can indicate the organ division whose stops

are labelled by the central PCB.

The Inner and outer PCBs

also label up to 20 stops on their lower 10 displays.

Their top displays can indicate the organ division whose

stops are labelled by the inner & outer

PCBs.

The PCBs are of high quality, and

professionally produced.

The image on the immediate right shows the Arduino Due

connector side, whilst that on the far

right shows the

OLED display side.

you will also need

to source and purchase:

- 60x 1.3" round

illuminated switches for 60 stops (20/40 reduce

accordingly);

- 240x spade connectors 120 red, 120

blue for 60 stops (20/40 reduce

accordingly);

- connectors for your chosen encoder & decoder (eg 10 x

40-way 0.1" SIL pin

strips);

- 1 x

64-port MIDI encoder (may be reduced to 32-port for a 20

stop build);

- 1 x 64-port MIDI decoder (may be

reduced to 32-port for a 20 stop build);

- 1 x 5v

PSU, 1 x 9-12v PSU, 1 x USB cable (micro-B to B-plug);

- a good supply of 0.05" 40-way ribbon cable and 3mm

heat shrink tubing.

Both images show PCBs with DIL

connector sockets fitted and soldered. Please note that PCBs

are NOT supplied with sockets, although they can be

fitted for an extra charge of £25 per PCB.

Prices are: £35 each, +

P&P.

1.3 The Arduino

Due(s) and kasLABS software

The

labelling system is driven by an Arduino Due microcomputer,

under the control of purpose-designed software,

kasLABS v3.x. The Arduino connects to the

three PCBs via special cables, which you makeup as part pf

the project, using 40-way DIL IDC connectors and 40-way

ribbon cable. The cables are all illustrated and described

very clearly in the Core Kit Construction Manual.

The

image below illustrates the connections between the Arduino

Due and the three PCBs. Other pictures in the Core Kit

Construction Manual provide further clarification, as do

also the online YouTube videos.

You will need two Arduino Dues, each with the software

installed, if you build two stop jambs. You may also send in

your own Arduino

Due(s) and have the soiftare installed

for a small additional charge. The Dues are supplied with

USB Device Names to identify which Due should be in your

left jamb, and which in your right. Therefore, if you are

ordering only one Arduino Due, please indicate whether you

are building a left or a rignt jamb. This will ensure that

your stop label text is formatted and justified to best suit

the position of your stop

jamb(s).

Prices are:

per single

Arduino Due including kasLABs

software installed and tested £70 + P&P.

per

single

copy of kasLABS software

installed into your own Arduino Due and tested £35 +P&P.

(Please note: to have your own Arduino Due loaded with the

software, you must provide return postage included with your

P&P).

1.4 Other

Components

You must provide the other

components yoursef: they are all readily available online in

most countries. Some may be available from KASpencer but

lead times are unpredictable.

Full details of all

components are given in the Core Kit Construction Manual.

Building the PCBs

Here is a list of the other components required for each

PCB:

- 12 x 0.1" 2 x 7 DIL PCB sockets*, or 3 x40-way 0.1" SIL socket strips**;

- 1 x 0.1" 2 x 7 DIL PCB pin header, or

1 x 40-way 0.1" SIL pin strips;

- 1 x 0.1" 2 x 20 DIL PCB pin header,

or equivalent 0.1" SIL pin strips;

- 12 x 7-pin SPI SH1106 (1.3") OLEDs;

- 1 x DIL IDC 0.1" 2x7

ribbon cable header plugs***;

- 1 x DIL IDC 0.1" 2x20 ribbon

cable header plugs.

(*DIL=dual in line;

**SIL=single in line, ***IDC=insulation displacing connector)

- a

good supply of 0.05" 40-way ribbon cable and 3mm heat shrink

tubing.

The picture on the right shows an OLED

mounted into a socket on the PCB.

Adding the

Illuminated Stop Switches

If you do not already

have stop jambs with suitable illuminated stop switches (or

solenoid driven drawstops),

you will have to install 60 on

each stop plate.

For the

Illuminated Stop Switches, you will need to

source and purchase:

- 60x 1.3" round illuminated switches for 60 stops;

- 240x spade connectors 120 red, 120 blue for 60 stops;

- connectors for your chosen encoder & decoder (eg 10 x

40-way 0.1" SIL pin strips);

- 1 x 64-port MIDI encoder;

-

1 x 64-port MIDI decoder;

-

1 x 5v PSU, 1 x 9-12v PSU, 1 x USB cable (micro-B to

B-plug);

- a good supply of

0.05" 40-way ribbon cable and 3mm heat shrink tubing.

Each switch will have to be wired to an input of a

60-way MIDI Encoder: a suitable scheme is described in

detail, including connectors and ribbon cable between the

switches and the Encoder.

The LED in each switch body

must be wired to an output of a 60-way MIDI Decoder: s

suitable scheme is described for this too, along with

a

ribbon cable for the connections between each LED and the

Decoder.

The PSU will connect to the commoned +ve or -ve

terminals (according to whether you have a "Common +ve" or

"Common -ve" Decoder) of the LEDs, whilst their other

terminal connects to the Decoder outputs. The Core

Kit Component Manual will help with all that too.

The Core Kit Construction Manual explains

exactly how to do all of the above, and how to integrate the

switches with the PCBs.